|

How Differentials Work (adapted from an article that I don't remember where I got it from!) FINE PRINT: The information presented here is merely meant as an opinion. Anything that you might do, or any actions that might result from using this information is your own blooming fault. There is no way that this information is guaranteed to be 100% correct anyhow.

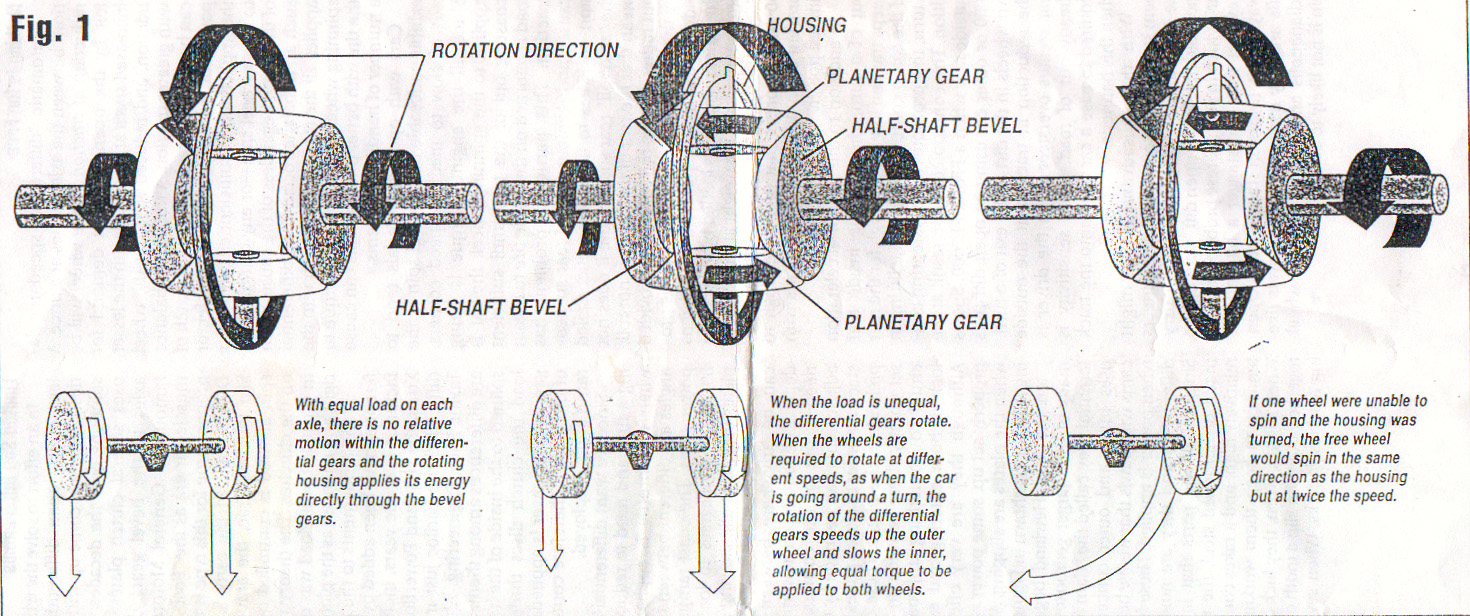

The drive axle on virtually every car manufactured in the 20th century uses a differential-but real mystery seems to surround its function and how it affects race car behavior. Since a car has some significant width, the wheels on cacti side describe different arcs as a car travels through a turn. The inside and outside wheels must rotate at different speeds to compensate for the difference in distance traveled. This is no problem on the front end (of a rear-drive car), but to accomplish this feat on the drive axle, some means must be provided to account for the required speed differential between the two wheels. . The most common device providing this function is called the "open differential." It uses a pair of bevel gears (also known as side gears, end gears or spider gears) splined to the drive axles (see Figure 1.). Another pair of bevel gears is arranged perpendicular to those on the axles, so that a square is formed, with the teeth of each gear mating with those on either side. A "ring gear" is bolted to the housing which encloses these gears, and this causes the housing to rotate when engine power is applied. As long as the load from the tires is equal at each axle, no relative motion occurs within the differential gears and the rotating housing applies its energy directly to the axles through the bevel gears. When the load between the wheels is unequal, however, such as when they are required to rotate at different speeds when going around a turn-the differential gears rotate, speeding up the outer wheel and slowing down the inner. In this way, equal torque can be applied to each wheel while allowing freedom of speed between them. Nothing

Is for Free Automatic "differential speed regulation" between the axles comes at a price. A reduction of traction at one wheel will be felt by the open diff as a demand for increased speed at the wheel with the lesser traction, and reduced speed at the wheel with greater traction. A traction imbalance can be created by either a slippery patch of pavement, a lot of lateral load transfer, or the application of sufficient engine power to cause wheel spin - or any combination of the three. Regardless of the cause, when such an imbalance occurs, the differential applies all the torque fed through it to the spinning wheel - and little or no torque to the tire with better traction. This can cause a number of handling problems. Cars

with open differentials tend to exhibit noticeable inner wheel spin at the exit

of slow to medium-speed corners. Since all the engine's torque is being applied

to the spinning wheel, the car is coasting out of the turn until sufficient load

is returned on the inside tire to regain traction. This particular problem has

caused an ingenious type of rear suspension on FVees to become prolific. Called

the "zero roll" rear suspension, it does not mean that the rear of the

car does not roll, but rather, that no roll stiffness is provided by the rear.

All of the roll resistance is provided by the front suspension, which keeps the

inner rear always loaded by at least the amount of unsprung weight at that

corner. While this unsprung weight may only 50 pounds or so, that may be enough

to prevent open diff wheel spin on cars with limited power. In

addition to this lack of acceleration out of a turn, the spinning inside rear

keeps traction low long enough for the rear of the car to come out. Much like

lifting in a turn, this promotes an over-steering condition. This condition can

also result at the outside rear when a FFord, FF2000, Sports 2000 or other car

using an open diff puts two wheels in the dirt at the exit of a turn. The

reduction in traction at the outside rear creates over-steer when the driver is

already out of road. Great sensitivity is required to ease a car back onto the

track when this happens. With these disadvantages, it might seem strange that some Indy car engineers use open diffs on long ovals. Larry Curry once remarked that an open diff "frees up the car" which in engineering terms probably means they can miss the stagger a bit and get away with it. (More on stagger later.) Open diffs are only used on the long ovals like Indianapolis and Michigan, where wheel spin is not likely to occur. Limited

Slip Differentials In

an effort to solve the problem of the open differential gear train designers

have come up with a number of solutions over the decades. One of these uses

several clutch plates coupling the axles to the bevel gears. It was made famous

by General Motors during the muscle car era as the "Posi-Trac,' but the

proper name for this type is the 'Salisbury Differential.' In the early

Salisbury units like the Posi-Trac, the amount of wheel spin allowed is

controlled by the preload on the clutches. The theory was great, but in practice

the preload was difficult to get right and changed as the plates wore. Many

refinements to the Salisbury differential have been added by other manufacturers

over the years, including one by Xtrac, the Hewland Powerflow and a new diff

called the Variloc introduced by Taylor Race Engineering. Although there are

differences among them, all use ramps splined to the inside of the housing which

load the clutch discs through the end gears when power is applied. The loading

of the discs is therefore controlled by the ramp angle employed. Since we want differential action entering a turn and need to reduce wheel spin when the throttle is applied, the ramp angles are different between the coast and power sides. The coast ramps are usually 80, 83 or 90 degrees to load the clutch plates little, if at all, allowing speed differentiation under braking. The drive ramps can be anywhere between 30 and 60 degrees depending on how much lock-up is needed out of the corners. Additional adjustments can be made by the type and stacking order of clutch plates used and by preload on the plates. These units can be set up anywhere between an open differential to something approaching fully locked, both entering and exiting turns. Although they are very effective when properly set up, some power is lost as heat when the plates are slipping. In

the '60s. Hewland began shipping many of their larger gearboxes with a

differential they called the “Cam and Pawl" It uses inner and outer

concentric fluted cam with pawls that wedge between them when power is applied.

These fully lock the differential and they are non-adjustable. Since all of the

parts that limit slip are made of hardened steel, the wear rate is relatively

high and it takes constant maintenance to keep them working correctly. When

slightly worn, they lock both wheels together, but then slip a tooth or two,

causing a series of jerks. When severely worn, they act like open diffs. Many

vintage cars that use Hewland gearboxes have extensively worn Cam and Pawl

differentials. In other words, open diffs. Another

type of limited slip differential that Ford popularized is the "Detroit

Locker." It uses a ratcheting mechanism that fully locks the differential

when power is applied and unlocks it when the throttle is lifted. Although that

action may be a bit abrupt, the real disadvantage appears when part throttle is

used. In these situations, it cannot decide whether to lock or unlock and jerks

until full power is applied. This can greatly affect traction in the mid-part of

a turn. The Detroit Locker supplies torque to the wheel that is rotating the

most slowly. In normal cornering, this is the inside wheel. Consequently, that

inner tire drives the front of the car toward the outside of the turn, causing

comer exit under-steer. Compared to other types of limited slips, the Detroit

Locker has few recommendations except by a few diehard road racers who continue

to use them- and by NASCAR. Torque

Biasing Differentials Limited slips are reactive. They limit over-speeding of the inner wheel by coupling it to the outer, more heavily loaded wheel. In contrast, "torque biasing" differentials are proactive. They send increased torque to the tire that is more heavily loaded prior to wheel spin. Two makes are in use in race cars, the Gleason-Torsen and the Quaife. Gleason made a few diffs for race cars in the '80s but are no longer producing them except for some Japanese street car manufacturers. The Quaife is virtually identical in operation and is still being produced.

Torque

biasing operation is based on the fact that worm gears transmit torque

efficiently only in one direction. In practice, side gears are coupled to each

axle and mate with several pair of overlapping planetary worm gears. These worm

gears float We

have two means of adjusting torque biasing differentials. The first is by the

helix angle and pressure angle of the gears; the second is by varying the number

of beveled washers exerting outward pressure between the end gears. However,

most racers who use them have no extra gears, so the only practical adjustment

is the preload or the end gears. While

they have the advantage of being proactive. torque biasing differentials are not

without faults. First, they are quite heavy and have a lot of mass concentrated

just inside the case, giving them quite a bit of rotational inertia. Second, a

fair amount of power is turned into treat due to the friction of all the gears

inside the case, and they never fully lock. Finally, they send more torque to

the more heavily laden outside wheel which, opposite to the effect of the

Detroit Locker, gives the car a power-on over-steering tendency. Here's a break-down view of a Quaife. Fully

Locked Differentials A

differential which is fully locked cannot really be properly called a

"differential," but it occupies the same physical space in the axle,

so we will consider it to be a fourth type. The simplest fully locked unit is

merely a steel machined part connecting each axle to the other and to the ring

gear. This part is called a “spool." Spools are light, have little polar

moment of inertia, no frictional losses and prevent inner rear wheel spin - so

why are they not more popular? The answer lies in the fact that, while the

torque biasing diffs and the limited slips help to reduce wheel spin out of the

corners to varying degrees, we do still need some provision to allow wheel speed

differentiation under braking (especially trail braking) entering a turn. A

spool cannot do this. The limitations of a fully locked differential don’t

bother many oval track racers, who overcome it with stagger, i.e., a difference

in tire size between the inside and outside rears. They rely on this stagger to

reduce or negate the wheel speed differential normally required. Thus, they are

quite happy with Spools. However, as a note of caution to those who only

occasionally, run ovals, the stagger must be perfect to do this, and even then,

a great deal of tire drag invariably occurs down the straights. When

they cannot obtain another type or find that it is out of reach financially,

many road racers use a slightly different form of a spool: the welded open diff.

To do this, an open differential has the spider gears welded together to prevent

them from turning. This effectively locks the unit up completely, although it is

heavier than a true spool. Exotic

Differential Types Many

other types of differentials have hit the market in the last few years, and some

are quite ingenious. One is a Salisbury type with an integral oil pump that

pressurizes the clutch packs once a wheel has begun to over-speed. Another uses

a computer-controlled DC motor to apply load to the clutches. Still another uses

eccentrics instead of gears. To completely replace traditional differentials

there are now some fluid couplings around as well. Time will tell if any of

these shake out as an evolution in differential design, or are merely good ideas

that did not work. For now, none of these exotic differentials are in widespread

use, and few of us have much likelihood of getting to play with them anytime

soon. So the question becomes, of those differentials we can utilize, which are

best and how should we use them? How

the Differential Affects Handling Open

differentials are required in FVee, FFord, FF2000 and S2000. To reduce wheel

spin, some competitors have tried shimming the side gears to within an-inch of

their lives to require more breakaway torque to initiate spinning. Tech

inspectors take a dim view of this, however, and one competitor lost a Runoffs,

win a few years ago in a Fford by doing this. With an open differential, roll

stiffness must be biased towards the front. It is not uncommon in these classes

to find 80 percent of the roll stiffness at the front. This allows most of the

lateral weight transfer to take place at the front and keeps the inside rear

more firmly planted, reducing the possibility of wheel spin. This is also the

reason that many competitors in these classes find the front tires go off before

the rear. Droop limiters at the front also help to reduce inner rear wheel spin

in open-diff cars. They are usually adjusted to allow only a fraction of an inch

of droop travel before the inside front tire is lifted off the ground. When this

occurs, the unsprung weight of that corner becomes sprung weight and being

cantilevered so far out to one side, some of this weight is then carried by the

inside rear tire, preventing the onslaught of wheel spin. Getting corner weights

perfect is probably more important on open diff cars for a similar reason. If

the one rear tire carries 30 pounds less weight than the outer, it will be much

more likely to spin when it is on the inside. Set

Up with a Limited Slip To

set up a car with any one of the limited slip or torque biasing differentials

described, some things need to be considered. Unlike an open diff, roll

stiffness at the front may be reduced to perhaps 60 percent. If an

under-steering condition on corner entry is a problem, the differential is most

likely not unlocking sufficiently to allow enough wheel speed variation. Use

less shim on a Quaife or Salisbury and a higher ramp angle (closer to 90

degrees) on the coast ramp of a ramp-equipped Salisbury. This recommendation

assumes that corner weights are properly set and no stagger exists. If

under-steer is encountered-beginning with power application in a turn, you need

to use more rubber up front, more track width, some Ackerman steering, or toe

out. Some teams that change differentials as part of a chassis set up use

different wheel offsets or wider tires when going to a differential with more

lockup. A shock problem could also account for this under-steer that only shows

up when more differential lockup is used (as many Ralt RT-5 owners know). If

under-steer occurs all the way through the corner, it is most likely

corner-entry under-steer, of which the driver was not able to rid himself

through his control inputs. Cure the corner entry under-steer and have a talk

with the driver. Differential-related

over-steer is always on corner exit and usually a result of wheel spin. If you

have a wheel spin problem in slow- to medium-speed corners) adjust the diff for

more lockup. If you can go to a fully locked diff and still have wheel spin, you

need less rear roll stiffness, more or softer rear rubber, or droop limiters on

the front. Only when you have exhausted these possibilities would you start

using traction control. Traction control works, but it works just like a driver

being tamer with his right foot. Since the object is to set up the car so that

the driver can keep the throttle open through as much of the lap as possible, it

seems to be going backwards to install a device that makes him back off on

corner exit. Traction control has its place, but only after the other factors at

our control have been optimized. Conclusion

To

be really fast, we must allow the driving wheels to: 1.

uncouple when the throttle is lifted 2.

Lock together smoothly and progressively when it is reapplied 3.

Avoid under-steer when the throttle is wide open again. The

payoff will be a car that is more stable, responsive and easier to drive at a

higher limit. HOME | MEMBERSHIP | CONTACT US | EVENTS | TECHNICAL | LINKS | FUN STUFF | PICTURES |